A former senior manager at Boeing’s 737 plant in Seattle has raised new concerns over the safety of the company’s 737 Max. The aircraft, which was grounded after two accidents in which 346 people died, has already been cleared to resume flights in North America and Brazil, and is expected to gain approval in Europe this week.

But in a new report, Ed Pierson claims that further investigation of electrical issues and production quality problems at the 737 factory is badly needed.

Regulators in the US and Europe insist their reviews have been thorough, and that the 737 Max aircraft is now safe.

In his report, Mr Pierson claims that regulators and investigators have largely ignored factors, which he believes, may have played a direct role in the accidents.

He explicitly links them to conditions at the company’s factory in Renton, near Seattle at the time. Boeing says this is unfounded.

Investigators believe both accidents were triggered by the failure of a single sensor. It sent inaccurate data to a piece of flight control software, called MCAS.

This automated system then repeatedly forced the nose of the aircraft downwards, when the pilots were trying to gain height. Ultimately each aircraft was pushed into an unrecoverable dive.

Efforts to make the 737 Max safe have focused on redesigning the MCAS software, and ensuring it can no longer be triggered by a single sensor failure.

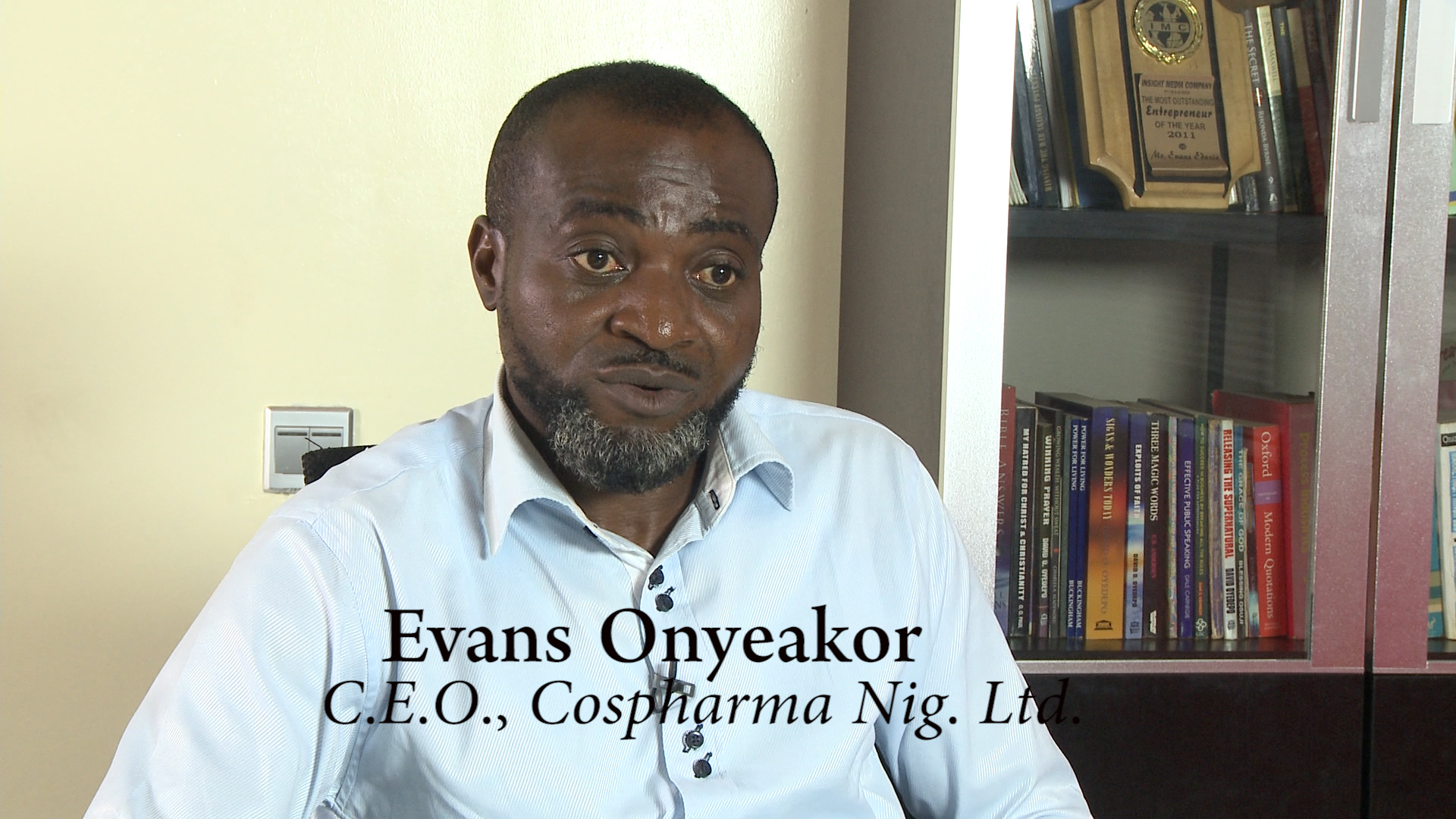

For Ed Pierson, this does not go nearly far enough. A US Navy veteran, who had a senior role on the 737 production line from 2015-2018, he was a star witness during congressional hearings into the disasters involving the Max.

He told lawmakers he had become so concerned about conditions at the factory, he had told his bosses that he was hesitant about taking his own family on a Boeing plane.

image captionEd Pierson (centre) at a House Transportation Committee hearing on oversight of the Boeing 737 Max certification, on 11 December 2019

He testified that during 2018, the factory was in a “chaotic” and “dysfunctional” state as, he claimed, staff there struggled under pressure from managers to build new planes as quickly as possible.

Now, he is worried that these issues have been overlooked in the rush to get the 737 Max back in the air.

His report draws on material from the official investigations. It claims that both of the crashed aircraft suffered from – what he believes – were production defects, almost from the moment they entered service.

These included intermittent flight control system problems and electrical anomalies that occurred in the days and weeks before the accidents.

He claims these may have been symptoms of flaws in the aircrafts’ highly complex wiring systems, which could have contributed to the erroneous deployment of MCAS. He also points out that sensor failures contributed to both accidents and asks why such failures were happening on brand new machines

Source: BBC